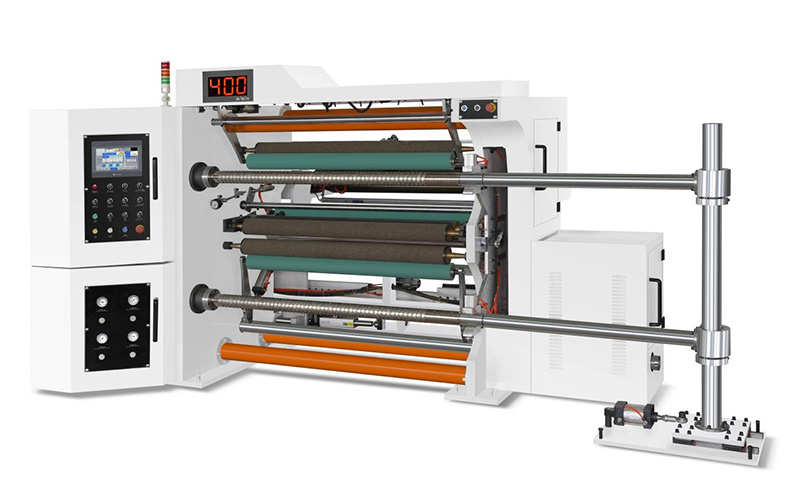

purpose

This machine is suitable for cutting various materials such as glass paper, PET, OPP, CPP, PE, PS, PVC, computer anti-counterfeiting labels, electronic computers, optical materials, film rolls, foil rolls, various paper rolls, film rolls, and printed materials

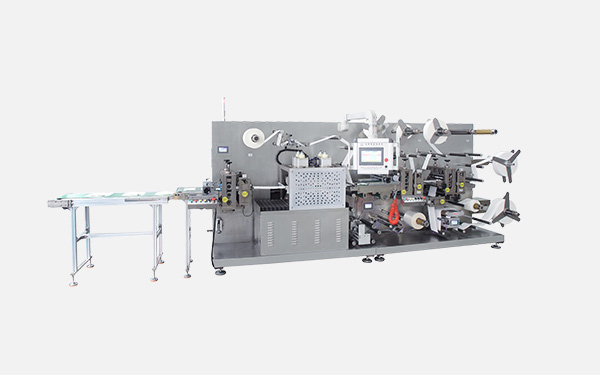

Host part

1. The main structure of the equipment adopts a steel plate structure

2. The spindle drive rod is made of seamless steel pipe processing. After tempering, surface hardening, electroplating, and dynamic balancing processing treatment

3. The main spindle drive main pressure rod is a rubber rod (Ding Qing rubber)

4. The feeding guide rod is made of metal rod (aluminum alloy material) and rubber rod (nitrile rubber material)

5. The host and material receiving transmission methods are synchronous wheel and synchronous belt transmission

6. All guide rods of the machine have undergone synchronous processing (using flat belts and synchronous belts), effectively preventing the stretching of materials

Material release mechanism section

1. The feeding mechanism is a one-piece feeding rack

2. Install a movable support with a linear guide as the moving device

3. The feeding adopts shaftless pneumatic lifting, which effectively saves labor and is easy to operate

4. Equipped with one set of deviation adjustment device, which can be adjusted left and right, front and back through the handwheel

5. The unwinding tension actuator is a pneumatic brake

6. The correction adopts the Bat brand

Part of the winding institution

1. The receiving shaft is equipped with two tile type inflation shafts

2. The locking method adopts pneumatic control

3. The winding tension is controlled by magnetic powder

4. Roll up rollers can be customized according to customer requirements (2 sets)

5. The cutting blade is equipped with 10 cutting frames or manually adjusted

6. Install 1 set of waste blowing device

Main parameters

Mechanical speed: 300m/min

Cutting speed: 300m/min

Discharge width: 1330mm

Narrowest material received: 50mm

Discharge diameter: Φ 600mm

Receiving diameter: Φ 450mm

Weight: 3500kg