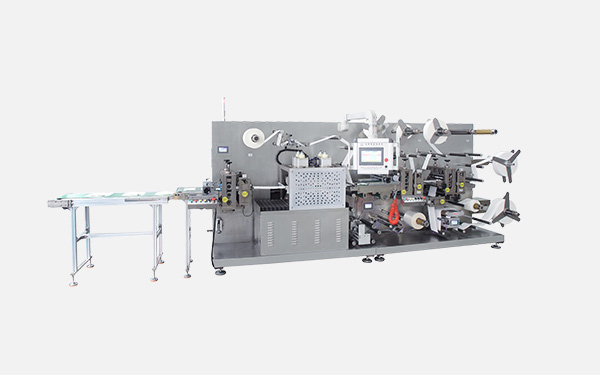

overview

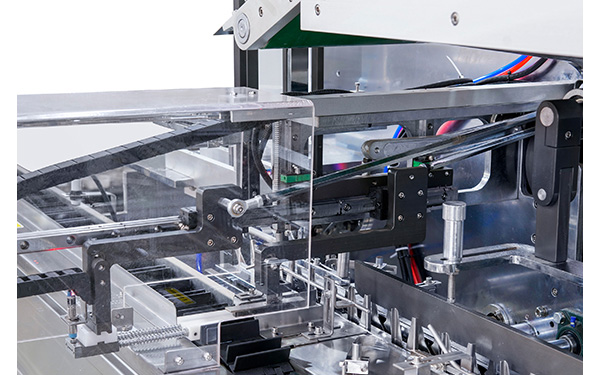

This device is a new model developed by our company in combination with advanced technologies at home and abroad,

integrating optics, electricity, gas, and machinery into a high-tech product. As a result, the performance and work

efficiency of the equipment have been significantly improved, meeting the requirements of fast packaging and

maintaining a stable and reliable state during rapid operation.

This machine is suitable for automatic feeding and cartoning of granular bags, soft double aluminum, pastes, band

aids, facial mask, coffee bags and other similar bagged items. The entire process of online material detection, manual

folding (1 to 4 folds) and transportation, paper box suction forming and transportation, material entry into the box,

batch number stamping, paper tongue packaging at both ends of the paper box (also applicable to hot melt adhesive),

missing material removal, and finished product output are all automatically completed.

characteristic

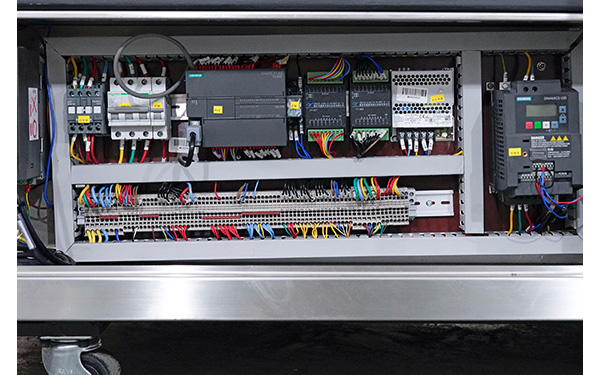

1. The PLC automatic control system, variable frequency speed regulation, and electrical components all use

internationally renowned brands

2. Adopting a human-machine interface operating system

3. Mechanical overload automatic shutdown.

4. Automatically remove paper boxes with missing packaging and instructions

5. Fault display, alarm, and finished product counting.

6. Stable performance and easy to understand operation.

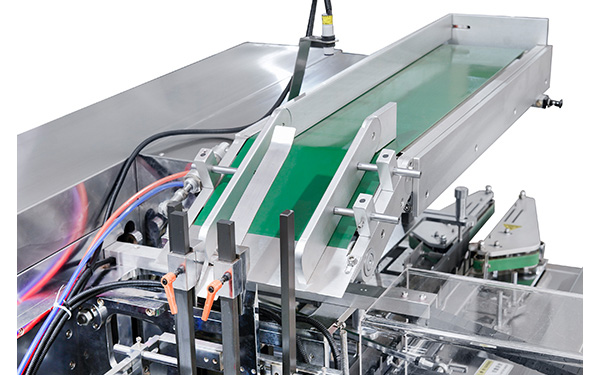

7. Automatic material feeding device, fully servo controlled, making the feeding position more accurate.

8. The fully automatic stacking device can achieve automatic feeding and discharging of materials.

9. Automatic tongue insertion device at both ends, and hot melt adhesive coating method can also be selected.

10. The PLC automatic control system, variable frequency speed regulation, and electrical components all use

internationally renowned brands.

11. Manual automatic folding feeding device.

12. Multiple sets of servo feeders to achieve multiple packages per box.

Technical Parameters

| Packing speed | 30-120 boxes/min |

| Bagged feeding bag | 1-12 bags (depending on bag size) |

| Quality requirements for paper boxes | 250-350g/㎡ (depending on the size of the cardboard box) |

| Paper box size range | (70-200)mm×(35-120)mm×(14-70)mm |

| Quality requirements for the instruction manual | 60-70g/㎡ |

| Unfolded size range in the instruction manual | (80-250)mm×(90-170)mm |

| Folding range of instruction manual | [1-4] Fold |

| Compressed air working pressure | ≥0.6mpa |

| Compressed air consumption | 200-240L/min |

| power supply | 220V/380v 50Hz |

| Main motor power | 1.5kw |

| External dimensions | 4590mm×1500mm×1750mm |

| Net weight of the whole machine | About 1500kg |