overview

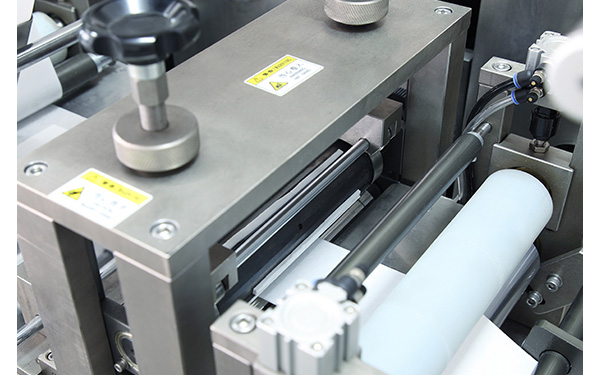

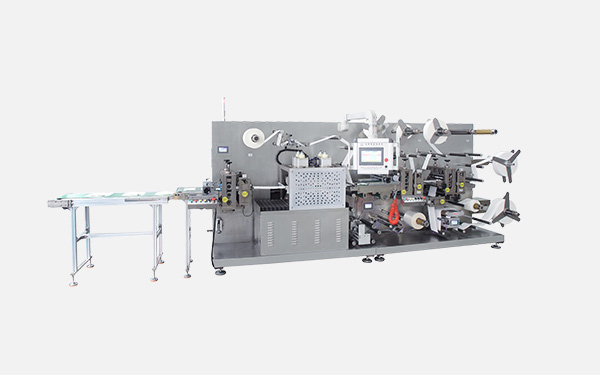

1. Used for general surgery and surgical procedures to protect wounds with indwelling needle adhesive molding machinery, which has advanced functions such as automatic peeling, pasting, compounding, cutting, and automatic waste collection of adhesive tape, PU film, absorbent pad, peeling paper, and release paper roll shaped materials.

2. This machine adopts imported seven servo motors, motion controllers, and human-machine interfaces. The servo correction positioning accuracy is high, the operation is convenient, and the performance is stable.

3. This machine can produce PU dressing adhesive, indwelling needle adhesive, medical dressing adhesive, plaster adhesive, eye adhesive, etc.

characteristic

1. The water absorbing cotton forming knife group and the dressing outer forming knife group are controlled by servo motor traction, which improves the forming accuracy and ensures a more beautiful appearance of the finished product.

2. Dressing adhesive absorbent cotton forming knife roller.

3. The dressing is attached to the outer forming knife roller.

4. Packaging material unwinding and rewinding device and automatic tension system.

Technical Parameters

| Model | FLT-300B |

| Cutting speed | 30m/min |

| Cutting width | 100-300mm |

| Cutting length | 50-350mm |

| positioning accuracy | ±0.2mm |

| total power | 5kw |

| power supply | ~380V ± 10% 50Hz (three-phase four wire) |

| External dimensions | 4000(L)×1100(W)×1950(H)mm |

| Whole machine weight | 2Ton |