overview

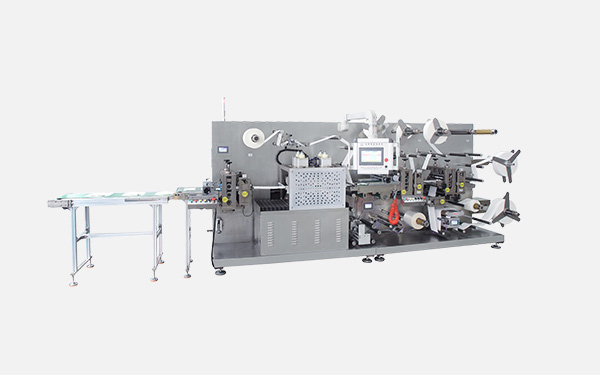

This machine is a four sided sealing and packaging machine developed by our company, designed and developed for the integration of automatic forming and packaging in the medical dressing industry. Suitable for automatic peeling, pasting, laminating, cutting, and forming of release paper roll materials for medical dressing stickers, PU dressing stickers, plaster stickers, eye stickers, and other products, followed by automatic packaging and bag making. The whole machine is driven by ten servo motors and adopts a motion controller to program the operation of the whole machine, including servo traction, batch number printing, reciprocating heat sealing, longitudinal and transverse cutting, and finished product conveying. The machine has superior performance and easy operation.

characteristic

This machine adopts imported servo motors, motion controllers, and human-machine interfaces, which are easy to operate and have stable performance.

The touch screen displays the host speed, cutting length, width, set bag length, heat sealing and feeding time, and output at a glance.

Imported photoelectric tracking color code, accurate graphic and text matching. Automatic temperature control to improve sealing quality.

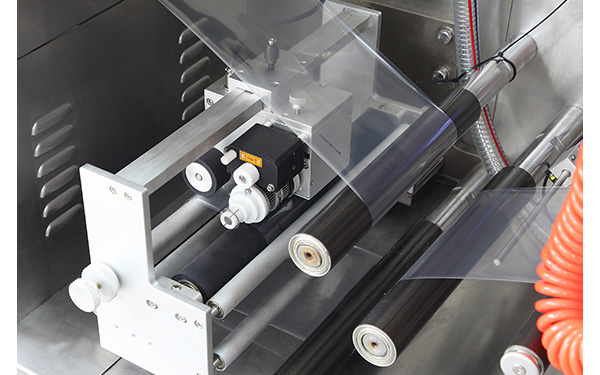

1. The water absorbing cotton forming knife group and the dressing outer forming knife group are controlled by servo motor traction to achieve higher forming accuracy and ensure a more beautiful appearance of the finished product.

2. The outer packaging finished product cutting blade group is controlled by full servo to make the blade edge smoother.

3. Batch number and production date information coding machine, ink wheel printing, reducing printing costs.

4. The reciprocating heat sealing forming device ensures a smoother and faster overall speed of the machine.

5. Apply absorbent cotton to the dressing and form the knife roller.

6. Automatic correction device for outer packaging materials.

7. External shaping knife roller for dressing application.

8. Packaging material unwinding device and automatic tension system.

Technical Parameters

| Model | YA-260 |

| Cutting width | 50-300mm |

| Cutting length | 50-300mm |

| positioning accuracy | ±0.5mm |

| Packaging speed | 30-150 packs/min |

| Maximum packaging film roll size | Φ400 |

| Maximum size of non-woven fabric roll | Φ600 |

| Size of absorbent cotton roll material | Φ600 |

| Size of release paper roll | Φ400 |

| Packaging film width | 320mm |

| air pressure | 0.5-0.7mpa |

| rated voltage | 380V, 50HZ (three-phase four wire) |

| total power | 25KW |

| machine weight | 3000kg |

| Machine dimensions | 6500×1250×1900mm |