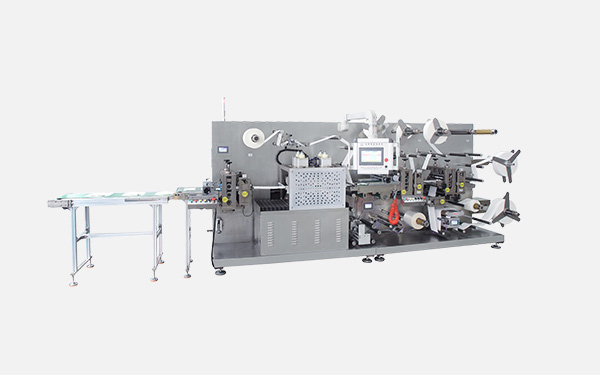

This machine is suitable for slitting various roll shaped materials such as BOPP, PP, PET, film, paper, non-woven fabric, fibers, etc. During the production process, the materials are cut and sliced according to different needs.

Performance and characteristics

1. This machine adopts a central winding and surface contact and winding method

2. Automatic meter counting, alarm and other functions;

3. The winding adopts A and B inflatable shaft structure, which is convenient for loading and unloading operations;

4. The unwinding adopts a photoelectric automatic correction system, which enables irregular materials to be cut normally

5. Flat blade longitudinal cutting waste edge automatic discharge device

6. Manual feeding, equipped with a 3-inch pneumatic valve shaft.

Technical parameters

1. The narrowest cut is 10MM (special materials subject to actual conditions)

2. Cutting thickness: 20g-150g/m2 (depending on different raw materials)

3. Maximum diameter of raw material unwinding: φ 800mm

4. Maximum diameter of raw material winding: φ 550mm

5. Maximum width of slitting material: 1100mm

6. Diameter of the gas expansion shaft for winding: 2 pieces (tile type) with a diameter of 76m (Rui'an Production Hope Brand)

7. Number of simultaneous coiling axes: 2

8. Correction accuracy: ± 0.5mm (specially made in Jiangsu)

9. Cutting accuracy: ± 0.5mm

10. Speed: 10-160m/min

11. Motor power: 4kw

12. Inverter power: 4KW (KOVO brand)

13. Body color: Silver white (other colors are optional)

14. Adopt automatic photoelectric correction (depending on different raw materials and specific customer requirements)

Machine configuration

1. Unwinding section:

(1) The rack adopts a steel plate structure with a thickness of 30MM

(2) Magnetic powder tension control: tension control range 10-50N

(3) The tension brake magnetic powder used for material release is 10 kg per piece

(4) The transmission guide roller adopts aluminum guide rod, which has undergone dynamic balancing treatment (diameter 80 1130m)

(5) The substrate can be adjusted left, right, and parallel: manual operation

(6) Correction accuracy of photoelectric correction system: ± 0.5mm. The correction host is driven by a 90 type synchronous motor

(7) Optical eye tracking correction

2. Roll up device

(1) Structure: Double inflation shaft, single arm rolling and winding method

(2) Adopting tile type inflatable shaft (specification: φ 76 × 1150m)

(3) Adopting 5kg magnetic powder clutch (Rui'an Shengda brand)

(4) Transmission method: using gear and chain transmission

(5) Roll diameter: φ 550mm

(6) Unwinding diameter: φ 800 mm

(7) Compression method: using cylinder top sleeve structure and back pressure shaft device

(8) Additionally equipped with 2 152mm winding air expansion shafts (key bar type)

3. Cutting section

(1) Adopting a straight blade longitudinal cutting device

4. Waste disposal device:

(1) Discharge method: Blow drying for waste disposal

(2) The main motor adopts a three-phase asynchronous motor (specification: 4kw)

5. Control section:

(1) The control system of this machine can be roughly divided into three parts: host control, tension control, and other control.

(2) Host control: including main motor control and main control box.

(3) Tension control: unwinding tension, winding tension, and automatic control have a wide speed range and good performance at both low and high speeds, resulting in excellent winding effect.

(4) Equipped with an electronic meter for measuring length; Alarm for parking; Automatic fixed length.

(5) Can be pre-set with cutting length shutdown

| Model | BY-C1100 |

| Effective width of equipment | 700 MM |

| waste discharge | Fan (750W) |

| Mechanical speed | 160M/minute |

| Maximum diameter of unwinding | Max 800mm |

| Maximum diameter of winding | Max 550MM |

| Roll up and roll paper core | Diameter 76/152 MM |

| STRAIGHT KNIFE | 8 pairs |

| Main motor | Motor (Shanghai Suchuan) |

| Mechanical total power | 4KW |

| Unwinding tension | Magnetic powder brake (5KW Shengda brand) with manual tension controller |

| Roll up method | Inflatable shaft (key bar style Wangyou card) |

| Roll up method | Double axis winding and inflation shaft (tile style Wangyou brand) |

| Winding tension | Clutch (5KW Shengda brand) with manual tension controller |

| Correction method | Photoelectric edge correction |

| Transmission mode | Chain gear |

| Roller | 80 diameter aluminum roller (strong light brand) |

| frequency converter | Kowo brand |

| electrical equipment | Zhengtai brand |

| bearing | national first-rate |