Overview

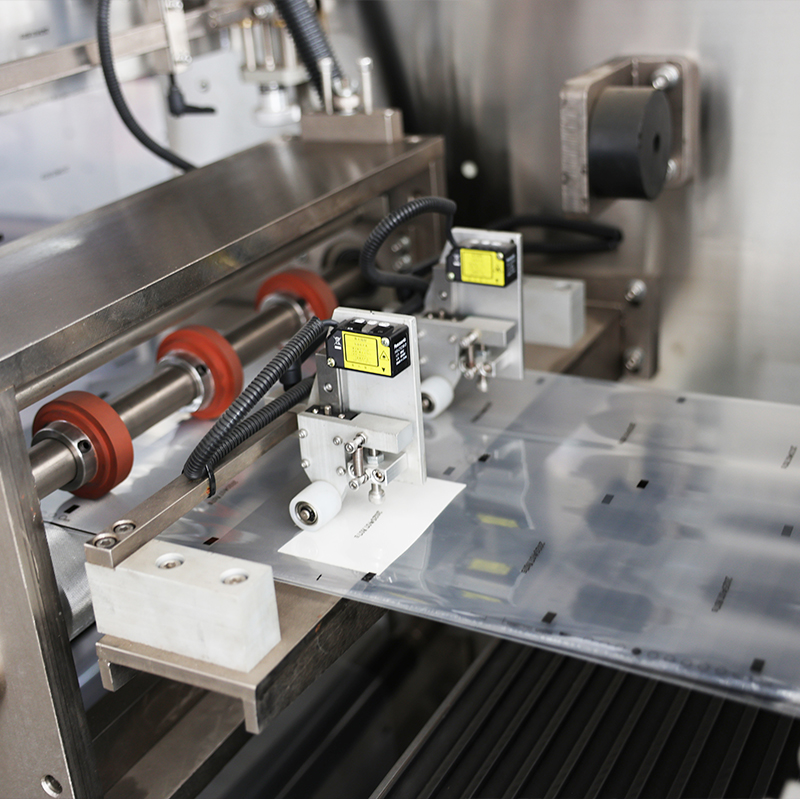

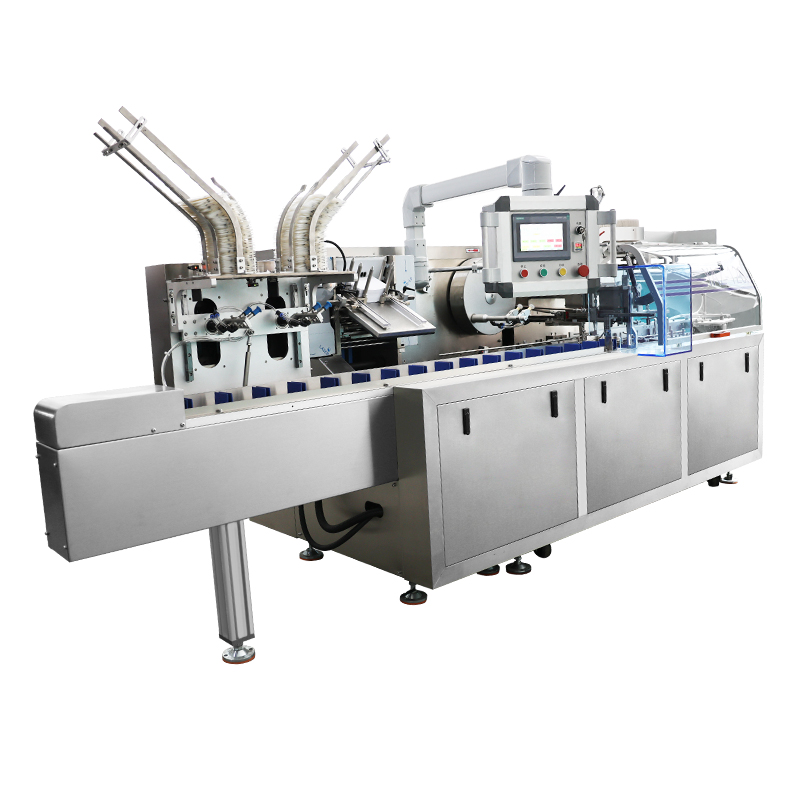

This machine is a packaging machine developed by our company, designed and developed for the integration of automatic forming and packaging in the medical dressing industry. Suitable for automatic peeling, pasting, laminating, cutting, and forming of release paper roll materials for medical dressing stickers, PU dressing stickers, plaster stickers, eye stickers, and other products, followed by automatic packaging and bag making. The machine has superior performance and easy operation.

Features

1) The host servo parameterized speed regulation can adapt to various packaging materials, and the whole machine is driven by servo motors, with good control performance such as adjustment and maintenance.

2) Touchscreen display, machine speed, packaging output, heat sealing time, etc. can all be displayed on the screen, making it easy to operate at a glance.

3) The coding machine automatically detects and rejects any missed codes.

4) Automatic detection and rejection of missing pieces.

5) The automatic temperature control and heat sealing parts use temperature controllers to automatically control the temperature, improving and ensuring the quality of heat sealing.

6) The heat sealing automatic tracking film can seal 6-15 bags in a reciprocating motion, and the heat sealing time and heat sealing tracking length can be adjusted within the specified range. The sealing is smooth, firm, and aesthetically pleasing.

7) Lack of membrane alarm and shutdown.

8) It can use various specifications of stickers, and can be equipped with an automatic feeder for 1-8 pieces according to the packaging material. It adopts multiple rows of channel feeding, which improves production efficiency.

9) Automatic detection and rejection of packaging film tape joints.

10) Ethernet remote control allows users and devices to negotiate iterative upgrade programs.

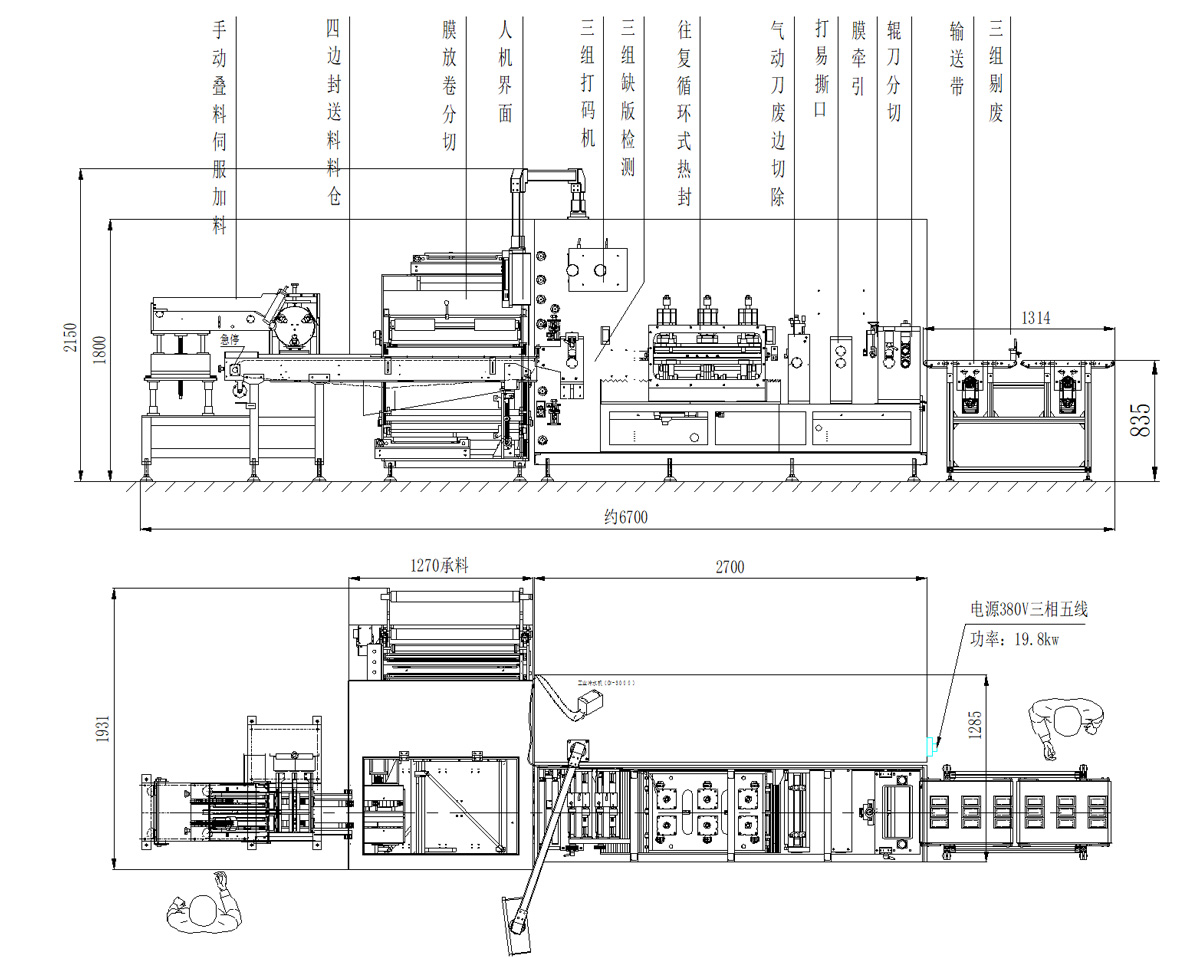

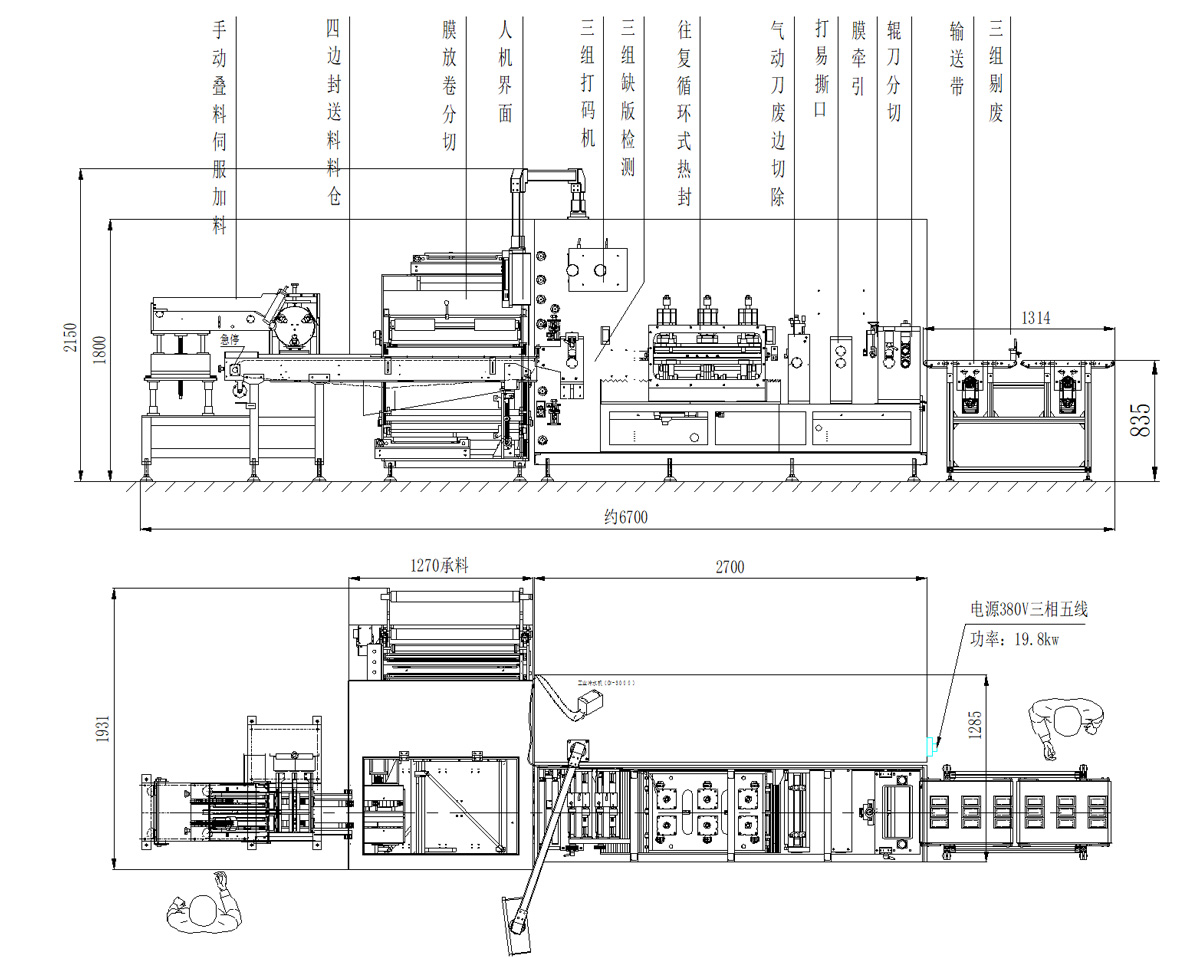

Whole machine schematic diagram

Technical Parameters

| Packaging capability | 60-240 packs/min |

| Maximum diameter of packaging film | 500mm |

| Maximum packaging size of the product | L200mm×W150mm×H5mm |

| compressed air | ≥0.5Mpa |

| Compressed air pressure | 0.3m³/min |

| Overall dimensions | 6800mm×2250mm×2150mm |

| Total weight | ≈5000Kg |

| operating noise | ≤75dB |

| heating power | 6kw |

| Total power | 22.5kw |

| power supply | 380V 50Hz |